As a renowned aluminum casting manufacturer, we specialize in delivering high-quality aluminum die casting and aluminum castings crafted to perfection. At Watry, we combine advanced technology with expert craftsmanship to produce components that meet the stringent demands of diverse industries. Our commitment to delivering precision-engineered solutions ensures that each casting stands up to rigorous performance standards. Whether in automotive, aerospace, or industrial applications, our aluminum castings provide durable and lightweight solutions that enhance efficiency and reliability. Trust in Watry’s expertise to drive innovation and excellence in your next project.

Aluminum Casting Manufacturer

Aluminum Casting Manufacturer - Aluminum Die Casting & Aluminum Castings

Our Aluminum Casting Capabilities

As experts in the field, our commitment to excellence in aluminum castings positions us as a leading manufacturer. We leverage the latest innovations and techniques in aluminum die casting to ensure we meet the highest industry standards. In this section, we’ll explore how our advanced processes and quality control make us a top choice in the market. From innovative casting techniques to adherence to industry standards, we’re dedicated to delivering superior products and services that cater to diverse applications.

Innovations in Aluminum Die Casting Techniques

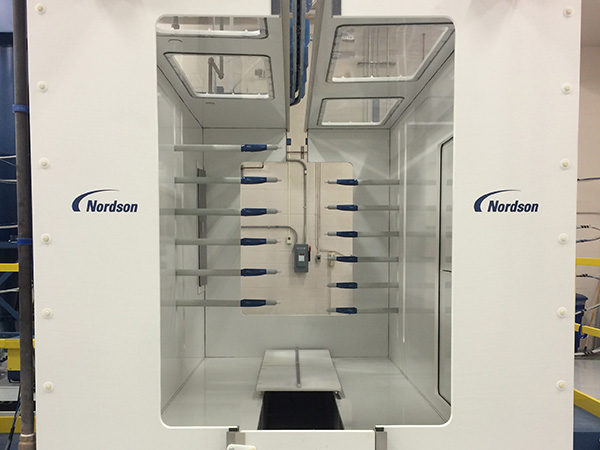

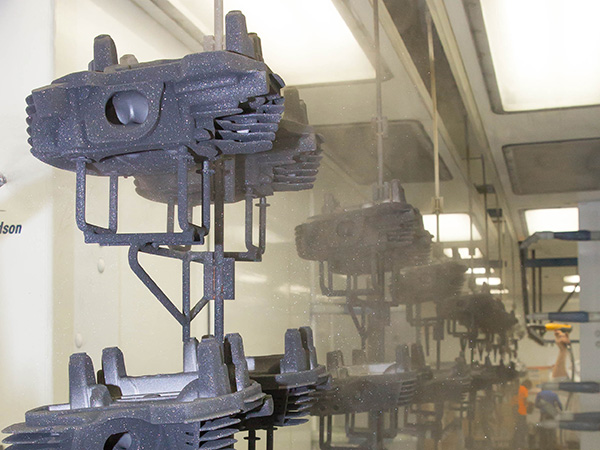

In the ever-evolving world of aluminum die casting, we’re at the forefront of innovations that redefine quality and efficiency. Our facility utilizes cutting-edge techniques that enhance the precision and durability of aluminum cast parts. By integrating advanced technology, such as automated die casting and real-time quality monitoring, we ensure each product meets rigorous specifications. This innovation not only elevates our processes but also boosts the quality of our aluminum casting products, aligning with both industry demands and client expectations.

Our focus on innovation extends to the materials we use. We select aluminum alloys that promise better thermal management and corrosion resistance. Such choices enable us to produce parts that are not only robust but also tailored for varied applications across industries. Whether it’s aerospace, automotive, or electronics, our dedication to leveraging the best materials and techniques sets us apart as a manufacturer. Through these advancements, we’re able to provide clients with products that embody our commitment to excellence and innovation.

Meeting Industry Standards with Boose Aluminum

Meeting and exceeding industry standards is a core focus at Boose Aluminum, where quality is paramount. We utilize precise die casting processes to ensure our aluminum cast products adhere to stringent industry standards. Each casting undergoes comprehensive quality checks, ensuring it meets our rigorous quality criteria before reaching the client. This dedication to quality not only reflects in our products but also builds trust and reliability with our clients.

Our partnership with industry bodies helps us stay updated with the latest standards and trends. Regular audits and certifications drive our manufacturing processes, ensuring our castings remain at the forefront of industry expectations. Furthermore, continual employee training fosters expert knowledge in the latest casting techniques and quality control measures. This focused approach guarantees our products are synonymous with quality, making us a trusted partner in delivering dependable aluminum cast solutions.

By integrating industry standards with innovative processes, we not only meet client expectations but often surpass them. This harmonious blend of expertise and quality is what makes Boose Aluminum a leading name in aluminum casting. Whether it’s for intricate die casting needs or bulk manufacturing, clients can count on us to deliver with precision and professionalism.

Comprehensive Die Design and Manufacturing

At Watry, the art of die design and manufacturing transcends traditional casting techniques, blending innovation with precision. Our foundry expertise ensures that every aluminum casting project is crafted with meticulous attention to detail. Through state-of-the-art mold manufacturing services, we offer unparalleled precision in die creation, crucial for enhancing the performance and longevity of aluminum castings. From conceptualization to execution, our team stands at the forefront of the industry, consistently pushing boundaries in design and manufacturing techniques. In this section, we’ll delve into how our foundry expertise assures precision, essential in creating high-quality cast products.

Ensuring Precision with Our Foundry Expertise

Precision in die design and manufacturing is a cornerstone of our operations at Watry. With years of experience, our team of skilled metal foundry workers meticulously crafts each mold to exact specifications, ensuring high-quality results. The process begins with comprehensive design where our experts use cutting-edge CAD technology to create detailed blueprints. This foundational step is essential in minimizing errors and enhancing the mold’s performance during the casting process. Our advanced software tools enable us to simulate the casting process beforehand, identifying potential issues and refining the design accordingly. Such precision in manufacturing guarantees that each die is perfectly suited to the specified casting needs, ensuring optimal mold fit and performance.

Our foundry expertise doesn’t stop at design. During the manufacturing phase, we employ state-of-the-art machinery that offers unparalleled precision and control over the die-production process. This ensures that each mold consistently meets stringent quality standards and provides reliable results during casting. Additionally, our team conducts rigorous inspections at every stage of production, from initial design to final manufacturing, to ensure the highest level of quality and precision. This detailed attention ensures that our aluminum castings perform reliably under various conditions, saving time and costs for our clients. Our dedication to precision extends beyond physical attributes and encompasses the holistic performance of the entire casting system. By leveraging our extensive foundry expertise, we consistently deliver products that embody innovation and quality, setting new benchmarks in aluminum die design and manufacturing.

Products and Applications of Aluminum Castings

Aluminum castings are pivotal in numerous industries due to their versatility, offering a range of products with countless applications. This section focuses on exploring the wide uses of aluminum castings in different sectors. From automotive to construction, these products bring unmatched benefits, including lightness and durability. We’ll delve into the uses that make aluminum castings indispensable across industries, highlighting how their applications contribute to performance efficiency and innovation. By understanding these versatile uses, it becomes clear how essential aluminum castings are in the modern manufacturing landscape.

Exploring Versatile Aluminum Product Uses

Aluminum castings offer exploring versatile uses across industries, from aerospace and automotive to electronics. As a metal foundry worker, I’ve seen them unlock innovative capabilities. In automotive, aluminum makes lightweight, durable components like engine blocks. Its ideal strength-to-weight ratio aids aerospace by enhancing aircraft construction. Electronics benefit from aluminum’s thermal conductivity, used for heat sinks. Construction materials use its natural corrosion resistance for window frames and roofing. Casting techniques provide flexibility, meeting industry demands and enhancing efficiency. Exploring these versatile applications of aluminum shows its pivotal role in various industries, always adapting to evolving operational needs.

Choosing the right aluminum casting manufacturer is pivotal to ensuring product durability and efficiency. At Watry, our commitment to quality and innovation in aluminum die casting delivers unparalleled results, crafted to meet the diverse needs of various industries. Our team of skilled metal foundry workers stands ready to guide you from concept through production, ensuring each casting is precisely engineered and exceeds your expectations. Partner with us to harness the benefits of our expertise, advanced technology, and unwavering dedication to excellence, and transform your project with aluminum solutions that set the benchmark for quality and performance.