Welcome to Watry Industries, your local solution for complex iron casting needs. With decades of experience in foundry services, we pride ourselves on delivering high-quality and innovative casting solutions tailored to meet the unique specifications of each project. Our dedication to precision and reliability ensures that each casting meets the highest industry standards, providing you with unparalleled performance and durability. Let our expert team guide you through the process, offering insightful advice for optimizing your designs. Discover how Watry Industries can be the trusted partner for all your iron casting endeavors.

Foundry Near Me

Watry Industries - Foundry Near Me for Complex Solutions in Iron Castings

Exploring Watry Industries' Expertise in Iron Castings

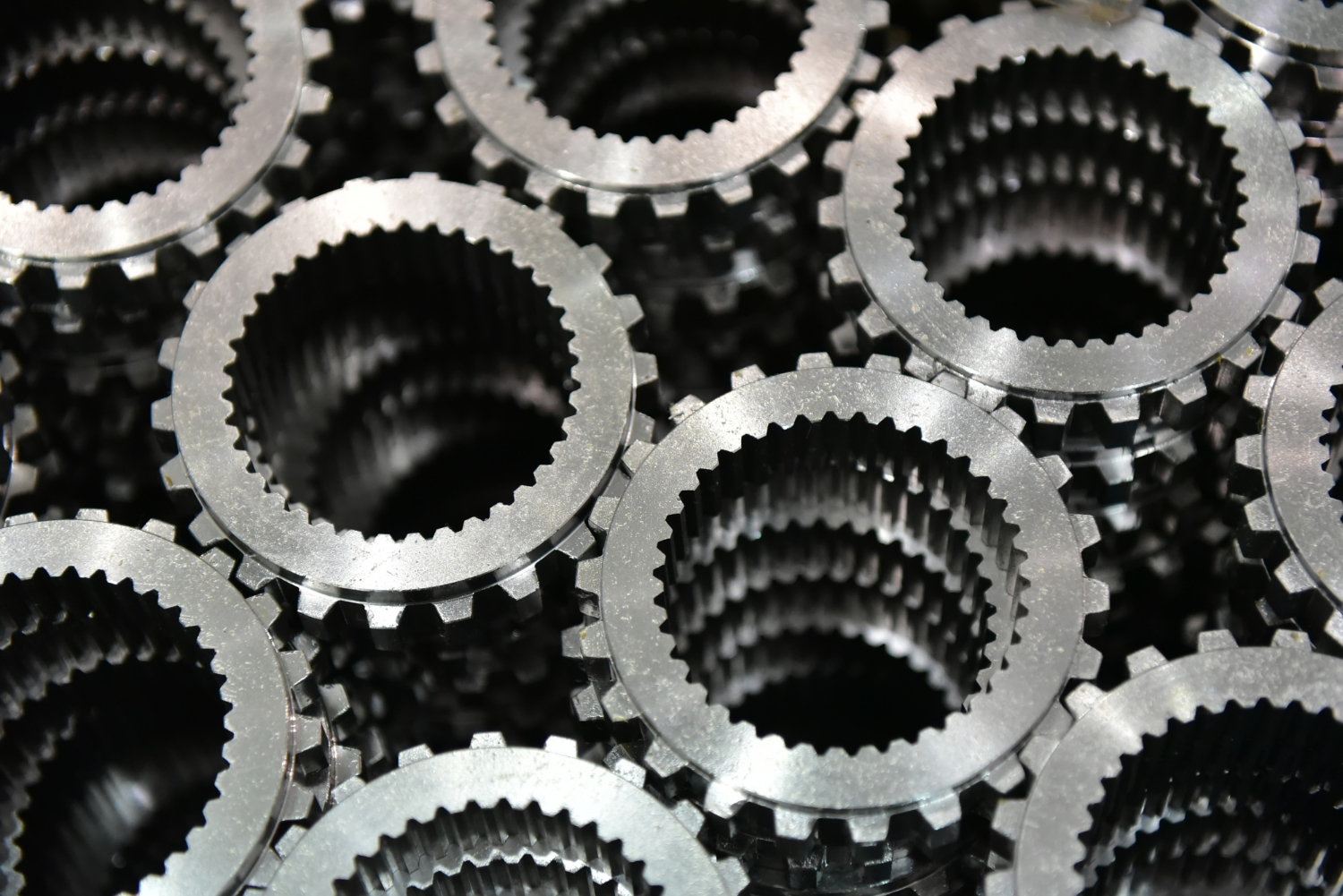

At Watry Industries, our expertise in iron castings is unrivaled, offering complex solutions for a wide range of industries. The role of iron in modern manufacturing is more significant than ever, and we specialize in producing both gray and grey iron castings to meet various specifications. Our foundry stands out by combining cutting-edge technology with traditional craftsmanship, ensuring precision in producing complex designs. In this section, we’ll explore how iron castings are crucial in modern manufacturing and how Watry Industries is at the forefront of this specialized field.

The Role of Iron in Modern Manufacturing

Iron has remained a cornerstone in manufacturing for centuries, but its role has evolved significantly in today’s modern landscape. As a metal foundry worker with years of experience, I’ve seen firsthand how iron casting is pivotal in producing durable and cost-effective components. In its various forms, including gray and grey iron, this material offers remarkable strength and wear resistance, making it ideal for both heavy machinery and delicate applications. At Watry Industries, we harness these properties to fabricate intricate castings that meet the growing demands for complexity and precision in manufacturing sectors worldwide.

In our foundry, the process of iron casting involves transforming molten iron into solid shapes that meet specific design requirements. This requires advanced methods and an understanding of the material’s properties under different conditions. Modern innovations in iron casting technology, such as computer-aided design and improved molding techniques, allow us to achieve unparalleled accuracy and efficiency. Our commitment to staying at the forefront of these developments ensures that every casting we produce not only meets but exceeds quality standards. It’s this dedication to excellence that makes Watry Industries a preferred choice for businesses seeking reliable and innovative solutions in iron castings.

Advanced Casting Techniques at Watry Industries

At Watry Industries, we’ve mastered advanced casting techniques that blend innovative technology with robust production processes, ensuring high-quality outputs every time. From initial design phases to the final production stage, our procedures ensure optimal efficiency and precision. In this section, we’ll delve into the complete casting process and how our refined methods stand out within the industry. By highlighting how we advance from design to production, you’ll gain insight into our dedication to craftsmanship and contemporary technology, underscoring our ability to meet intricate specifications within tight timeframes.

From Design to Production: The Casting Process

Embarking on the casting journey at Watry Industries begins with a core focus on design and precision technology. Our process is rooted in a detailed analysis of design specifications, ensuring every casting fulfills stringent requirements. Initially, our engineers collaborate closely with our clients to translate complex ideas into practical designs through advanced computer-aided design technology. This step is fundamental in laying out the intricate details that each casting needs, allowing us to foresee potential challenges and streamline the production process. Once the design stage is meticulously completed, we transition into the actual casting phase, where sand is crucial. Utilizing controlled environments, we employ advanced sand molding techniques that support the formation of complex shapes and geometries without compromising on detail or stability.

During this phase, our foundry taps into cutting-edge production technology to handle the molten materials, transforming them into solid structures that maintain the integrity of the initial design. Time is a critical factor in this stage, as each moment of the cooling process can significantly affect the casting’s final properties. The synchronization of design and production ensures that the output consistently meets our industry-leading standards for quality and durability. By implementing these advanced practices and maintaining a harmonious flow from design to completion, Watry Industries solidifies its position as a leader in the foundry sector, delivering unmatched reliability and innovation in every iron casting we produce.

Why Choose Watry Industries for Your Badger Alloys Needs

Choosing the right partner for your Badger alloys needs can significantly impact the quality and performance of your castings. Watry Industries stands out for its commitment to quality assurance and unmatched expertise. By merging traditional techniques with modern methodologies, we ensure precision and durability in every casting project. In this section, we’ll delve into our industry-leading quality assurance processes and the expertise that makes us a trusted leader in the realm of Badger alloys.

Quality Assurance and Expertise in Badger Alloys

At Watry Industries, ensuring the quality of Badger alloys castings is paramount. Our approach is structured around rigorous quality assurance protocols, which are integrated at every stage of the casting process. From selecting high-grade alloys to employing precise casting techniques, every step is designed to uphold the utmost in quality and reliability. Our facilities are equipped with state-of-the-art tools and testing equipment that allow us to monitor and control the entire casting process meticulously. This ensures each product not only meets but exceeds industry standards, providing our clients with the assurance of performance and longevity. Additionally, the expertise of our team plays a vital role. As seasoned metal foundry workers, we bring a wealth of knowledge to every project, drawing from years of experience one element that consistently sets us apart from the competition. Our understanding of the material properties and casting dynamics enables us to tackle even the most complex of projects with confidence. Leveraging both experience and innovation, we excel in crafting solutions tailored to the specific needs of our clients, guaranteeing satisfaction in every alloy casting. Our dedication to quality is not just a standard, but a foundation upon which we build trust with our clients. This commitment is evident in the precision and excellence demonstrated in each casting, reaffirming Watry Industries as a leader in the production of high-quality Badger alloys castings. By choosing Watry, you secure a partnership that prioritizes exceptional craftsmanship and cutting-edge expertise.

Innovations in Custom Castings at Watry

At Watry Industries, we lead the way in transforming the landscape of custom castings through technological innovations. Our foundry is renowned for combining advanced methods with time-honed skills to produce superior solutions tailored to client demands. This section explores the role of technology in our custom casting process, highlighting how we ensure superior outcomes in every project. From utilizing state-of-the-art tools to pioneering novel techniques, we offer insights into our commitment to excellence in custom castings.

Utilizing Technology for Superior Custom Castings

In the ever-evolving world of metal casting, technology is a pivotal driver of innovation. At Watry Industries, we pride ourselves on leveraging cutting-edge technology to deliver superior custom castings that meet precise specifications. Our foundry employs computer-aided design (CAD) software, which allows us to create detailed models and run simulations before the actual casting process begins. This proactive approach enables us to foresee potential challenges and adjust designs accordingly, ensuring the highest level of precision and effectiveness. Furthermore, our technological toolkit extends to advanced molding techniques, where we use automated molding machines that boost efficiency and minimize human error, giving us an edge in maintaining consistent quality. In addition, we incorporate data-driven processes to refine each casting’s properties, making use of sophisticated metallurgical software to analyze and predict outcomes based on different alloy compositions. This attention to detail in our custom castings process allows us to push the boundaries of traditional methods, delivering more complex geometries and robust components that stand the test of time. Crucially, these innovations don’t just enhance the physical properties of our castings; they also improve our environmental impact by optimizing resource use and reducing waste. Our commitment at Watry Industries to technological advancements not only showcases our leadership in the foundry sector but also strengthens our ability to meet the dynamic needs of diverse industries. This dedication to harnessing technology ensures that we provide solutions that are not only superior but also sustainable and forward-thinking. As a metal foundry worker who has witnessed these advancements firsthand, I can attest to their transformative impact on the quality and efficiency of our custom castings, setting a new standard for excellence in the industry.

The Importance of Selecting the Right Foundry

Choosing the correct foundry significantly impacts the quality and performance of iron castings. At Watry Industries, we believe in offering more than just casting solutions; we provide comprehensive support, ensuring that each client’s unique needs are met with precision. This section underscores why selecting a foundry is crucial, emphasizing how our consultation and support services set us apart. We’ll explore the meticulous approach we take to guide our clients, from initial consultation to ongoing support, ensuring that every casting project results in a successful outcome.

Consultation and Support Services at Watry Industries

Watry Industries places immense value on the consultation and support services we offer our clients. Selecting the right foundry involves more than assessing capabilities and facilities; it’s about finding a partner who understands your project’s specific needs and challenges. Our consultation process begins with an in-depth discussion with our clients, allowing us to comprehend every project detail, from the complexity of design to the specific iron casting requirements. This collaborative approach ensures that we align our services with our client’s goals, achieving optimal results in every casting endeavor. Furthermore, our steadfast commitment to support extends well beyond the initial consultation. We provide ongoing guidance, leveraging our expertise to troubleshoot and resolve challenges that may arise during production. This proactive stance not only enhances the quality of our outputs but also fosters a strong relationship between our team and clients, based on trust and mutual understanding. At Watry Industries, we believe in standing alongside our clients every step of the way, providing insights and solutions that drive success. Our dedication to exceptional service demonstrates why Watry Industries should be your choice when selecting a foundry. Our unrivaled expertise, coupled with our inclusive support offerings, positions us uniquely to address intricate specifications and deliver superior iron casting solutions for varying industries.

Choosing Watry Industries as your foundry partner means opting for unparalleled expertise in delivering complex iron casting solutions. Our dedication to precision, advanced technology, and customer satisfaction positions us as a leader in the industry. Whether your project demands intricately detailed components or robust large-scale productions, we are committed to bringing your vision to life with reliability and excellence. Let Watry Industries not just be a foundry near you, but a trusted partner capable of exceeding your casting expectations. Reach out today and discover how we can help streamline your manufacturing process.