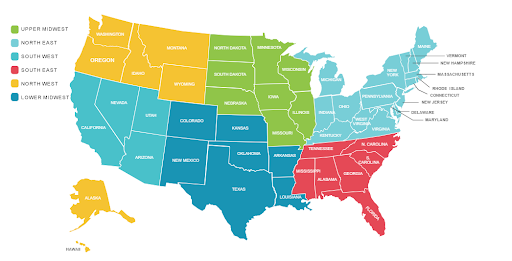

At Watry, we proudly serve the entire United States, offering top-notch aluminum casting solutions that align with various industry needs from the tech-driven regions of the Southwest to the industrial hubs of the Upper Midwest. Our comprehensive service areas include strategic focus in every major U.S. region, ensuring we’re well-equipped to handle your specific requirements with precision and innovation. Whether you’re in the bustling automotive sectors of the Southeast or the aerospace-centered locales of the Northwest, we’re here to boost your project’s success with state-of-the-art casting technologies and a commitment to quality that stands out. Discover how our tailored services can elevate your operations.

Service Area – National

National Aluminum Casting Foundry

Expanding our reach across the nation, Watry Industries proudly serves a diverse array of industries from coast to coast. As we respond to national demand, we’ve noticed significant shifts in industry trends that push us toward continuous innovation in our aluminum casting services. Our commitment to casting innovations isn’t just about staying current; it’s about leading the way in our field to ensure the highest level of customer satisfaction.

We’re not just expanding our services; we’re enhancing them. Our service expansion plans are meticulously designed to meet the evolving needs of our clients, wherever they’re located. Through strategic investments in technology and processes, we’ve improved our capacity to deliver high-quality, precision-cast products more efficiently than ever before.

North West:

Washington, Oregon, Idaho, Montana, Wyoming, Alaska, Hawaii

In the Northwest, from the lush landscapes of Washington and Oregon to the rugged terrains of Montana and Wyoming, along with the unique environments of Alaska and Hawaii, we at Watry Industries are actively extending our premier aluminum casting services. We’ve adapted by implementing strategic partnerships within these regions to improve delivery times and reduce environmental impact. Our efforts ensure that even the most remote locations benefit from advanced aluminum casting technologies, reinforcing our role as a leader in the global aluminum casting market.

Upper Midwest:

North Dakota, South Dakota, Nebraska, Minnesota, Iowa, Missouri, Wisconsin, Illinois

Turning our attention to the Upper Midwest, states like North Dakota, South Dakota, Nebraska, Minnesota, Iowa, Missouri, Wisconsin, and Illinois play crucial roles in our aluminum casting operations. This region, rich in manufacturing history, aligns perfectly with the market demands and industry trends that drive our business forward.

We’ve noticed a significant uptick in customer expectations here, pushing us to innovate continuously and ensure our casting solutions meet precise standards. The Upper Midwest offers distinct regional advantages that benefit our operations, including a robust transportation network and a skilled labor force well-versed in industrial manufacturing.

These factors not only enhance our logistical capabilities but also improve our service delivery across these states. We’re tuned into the evolving needs of industries in this area—from automotive to industrial machinery—which informs our strategic planning and operational adjustments.

North East:

Michigan, Indiana, Kentucky, Ohio, West Virginia, Virginia, Maryland, Pennsylvania, Delaware, New Jersey, New York, Connecticut, Rhode Island, Massachusetts, New Hampshire, Vermont, Maine

Our focus now expands to the North East, where states like Michigan, Indiana, Kentucky, Ohio, West Virginia, Virginia, Maryland, Pennsylvania, Delaware, New Jersey, New York, Connecticut, Rhode Island, Massachusetts, New Hampshire, Vermont, and Maine present new opportunities. As we continue to expand, we’re dedicated to delivering the highest-quality aluminum castings to these vibrant markets. We believe that our strategic presence in the North East won’t only enhance our service offerings but also strengthen our relationships with key industry players, driving mutual growth and success.

South West

California, Nevada, Utah, Arizona

We now set our focus on the South West, covering the dynamic markets of California, Nevada, Utah, and Arizona. Each state brings unique contributions to our aluminum casting operations, driven by regional demands and technological advancements. Together, these states help us push the boundaries of aluminum casting, setting benchmarks for innovation, partnership, customization, and efficiency.

Lower Midwest:

Colorado, New Mexico, Kansas, Oklahoma, Texas, Arkansas, Louisiana

Shifting our focus to the Lower Midwest, including states like Colorado, New Mexico, Kansas, Oklahoma, Texas, Arkansas, and Louisiana, our aluminum casting operations tap into a diverse economic landscape characterized by significant industrial growth. We’re seeing exciting regional manufacturing trends with an influx of tech-driven industries and energy sectors demanding high-quality aluminum casting innovations.

We’re not just responding to needs; we’re anticipating them, collaborating closely with local industries to drive mutual growth. We’re excited to continue expanding our reach and refining our technologies in the Lower Midwest, ensuring that our partners always have the best in aluminum casting services at their fingertips.

South East:

Tennessee, North Carolina, South Carolina, Georgia, Alabama, Mississippi, Florida

As we extend our reach into the South East, states like Tennessee, North Carolina, South Carolina, Georgia, Alabama, Mississippi, and Florida offer a wealth of opportunities for our aluminum casting services. Each state’s unique industrial landscape not only encourages growth but also challenges us to continually enhance our service offerings. We’re excited to partner with local industries and contribute to the regional economy through our specialized aluminum casting solutions.

Capabilities

At our foundry, we’ve expanded our capabilities to include a comprehensive range of services such as casting design consultation, mold and fixture design and build, as well as heat treating.

We also offer precision CNC machining and powder coating to meet the stringent requirements of our diverse clientele. Each of these services is tailored to enhance the quality and performance of your aluminum casting projects.

Casting Design Consultation

We understand the complexities involved in aluminum casting and offer specialized casting design consultation to meet your unique needs. Our expert team works closely with you to select the most effective casting techniques, ensuring that every project is tailored for optimal performance and cost-efficiency. We’re not just about creating; we’re about innovating solutions that fit precisely with your requirements.

Design optimization is at the heart of what we do. We analyze each aspect of your proposed product and refine it to enhance functionality while reducing unnecessary bulk and material wastage. This approach not only improves the overall quality but also impacts the durability and lifespan of the cast parts. Our material selection process is driven by both application-specific requirements and environmental considerations, ensuring sustainability without compromising on strength.

Additionally, our tooling strategies are designed to maximize production efficiency. We help you develop prototypes that serve as a real-world proof of concept, allowing for adjustments before full-scale manufacturing begins. This step is crucial in avoiding costly reworks and delays, ensuring that the final product exactly meets your specifications. With Watry, you’re set for success right from the start.

Mold and Fixture Design/Build

Building on our extensive experience in aluminum casting, our capabilities in mold and fixture design/build are second to none. We’re always at the forefront of mold technology advancements, ensuring that every design leverages the latest innovations to enhance product quality and production efficiency.

Our team excels in fixture design innovations, crafting tailored solutions that perfectly fit the unique requirements of each project. We don’t just design; we innovate. By integrating cutting-edge casting material selection into our mold-making process, we ensure optimal performance and longevity of the cast products.

This meticulous attention to material specifics significantly boosts the final product’s quality and durability. Moreover, we’ve developed comprehensive mold durability testing protocols to guarantee that every mold not only meets but exceeds industry standards.

This rigorous testing ensures our molds withstand various production environments, maintaining high precision in mass production. Our fixture optimization strategies are designed to maximize production throughput while minimizing waste and downtime.

Heat Treating

Shifting our focus from mold and fixture design/build, our expertise extends to the specialized process of heat treating aluminum castings. At Watry, we’ve perfected various heat treating techniques that enhance the durability and performance of our castings.

Our state-of-the-art heat treating equipment allows us to execute precise thermal processes, essential for achieving optimal material properties. The benefits of heat treating are significant. This process not only increases the strength and hardness of aluminum castings but also improves their resistance to wear and fatigue.

It’s particularly beneficial in applications where components are subjected to high mechanical stresses. Through careful control and implementation of heat treating standards, we ensure that each casting meets rigorous quality specifications.

We serve an array of industries with our heat treated aluminum castings. From automotive to aerospace, our clients rely on us for parts that require exceptional mechanical properties and reliability. Adhering to established heat treating standards, we guarantee that our processes are consistent, reproducible, and tailored to meet the specific needs of each application.

Precision CNC Machining

As our expertise in aluminum casting services continues to expand, precision CNC machining stands out as a critical capability at Watry Industries. We’ve integrated CNC machining innovations into our operations, enabling us to offer custom machining solutions that meet diverse and complex customer needs. Our advanced machining applications are tailored to enhance the precision and efficiency of every project, ensuring top-tier results.

We utilize precision tooling techniques that significantly increase the accuracy and detail of our aluminum castings. These methods allow us to execute intricate designs that are crucial for high-performance components in various industries. Our commitment to quality is reflected in our stringent quality control processes, which monitor and ensure the consistency and excellence of every piece we produce.

Our team’s expertise in CNC machining brings your concepts to life with unparalleled precision. Whether it’s small-scale prototypes or large-volume production runs, we guarantee advanced solutions that push the boundaries of what’s possible in aluminum casting. With Watry, you’re not just getting a supplier; you’re gaining a partner dedicated to driving your project’s success through innovative machining and meticulous attention to detail.

Powder Coating

We’ve mastered precision CNC machining and now bring that same commitment to excellence to our powder coating capabilities. The powder coating process we employ is designed to enhance both the aesthetic appeal and durability of our aluminum cast products. We apply a dry powder—typically a mix of finely ground particles of pigment and resin—uniformly over the surface, which is then cured under heat to form a hard coating.

The benefits of powder coating are extensive. It’s not only more environmentally friendly than traditional liquid coating—due to the absence of volatile organic compounds—but it also provides your components with superior durability and resistance to chipping, scratching, and fading. This makes it an ideal choice for a wide range of applications where durability is critical.

At Watry, we choose powder coating materials meticulously, ensuring they meet the specific needs of our diverse clientele. Whether you’re in the automotive, industrial, or consumer goods sector, we tailor our solutions to fit your unique requirements.

Assembly

At Watry, we often extend our expertise beyond casting and coating to include comprehensive assembly services. Our team is skilled in a variety of advanced assembly techniques, ensuring each component integrates seamlessly for optimal functionality. We’re committed to assembly efficiency, streamlining processes to reduce turnaround times without compromising on quality. Our facility leverages assembly automation to enhance precision and speed. This technology allows us to maintain consistent assembly quality across all projects, large or small.

We understand that the integration of automated systems isn’t just about keeping up with trends; it’s about providing you with the best possible outcomes in every project we undertake. Moreover, our approach to assembly integration considers every aspect of production. This holistic view ensures that all parts not only fit together perfectly but also function as intended in their final application.

By focusing on the finer details of assembly, we uphold our reputation for quality and reliability. Let us handle the complexities of assembly so you can focus on what you do best. With Watry, you’re not just getting a supplier; you’re gaining a partner dedicated to your project’s success.

Finishing and Testing

Our finishing and testing capabilities ensure that every aluminum casting meets the highest standards of quality and performance before reaching our clients. We’re committed to integrating top-notch finishing processes and rigorous testing standards into every project. By applying advanced surface treatments and utilizing precise inspection techniques, we uphold our reputation for quality assurance with each casting we produce.

From deburring to high-spec polishing, our array of finishing options is tailored to enhance the durability and appearance of our products. We don’t just look at aesthetics; we ensure that each piece can withstand the demands of its operational environment.

Our testing procedures are equally thorough, encompassing both destructive and non-destructive methods to verify integrity and functionality. We conduct pressure tests, X-ray inspections, and spectral analysis to detect any internal or surface flaws that could impact performance.

Working With Watry for your Aluminum Casting needs

Choosing Watry Industries for your aluminum casting needs means partnering with a leader in the industry recognized for innovation, quality, and reliability. We’re at the forefront of casting innovations, constantly refining our processes to deliver the best results. Our facilities are equipped with the latest in robotic automation, ensuring precise and consistent aluminum casts time after time.

But it’s not just about advanced machinery; our commitment to quality assurance means each project meets stringent standards before leaving our foundry. We value industry partnerships and customer collaboration, believing that working closely together brings out the best in what we can achieve. Our history of cooperation, such as with Mercury Marine, has taught us that collective expertise leads to groundbreaking solutions in casting technology. By aligning our innovative techniques with your specific needs, we ensure that the final product isn’t just satisfactory but surpasses expectations.

At Watry, we’re more than just a supplier; we’re your trusted partner in the complex world of aluminum casting. Let’s work together to turn your concepts into high-quality, durable products that stand the test of time.

At Watry Industries, we’re proud to serve every corner of the nation with top-tier aluminum casting services. Whether you’re in the heat of Texas or the chill of Alaska, our advanced techniques and commitment to quality ensure your needs are met with precision. Trust us to bring your projects to life with reliability and excellence. Let’s create something remarkable together. Choose Watry for your next aluminum casting challenge.