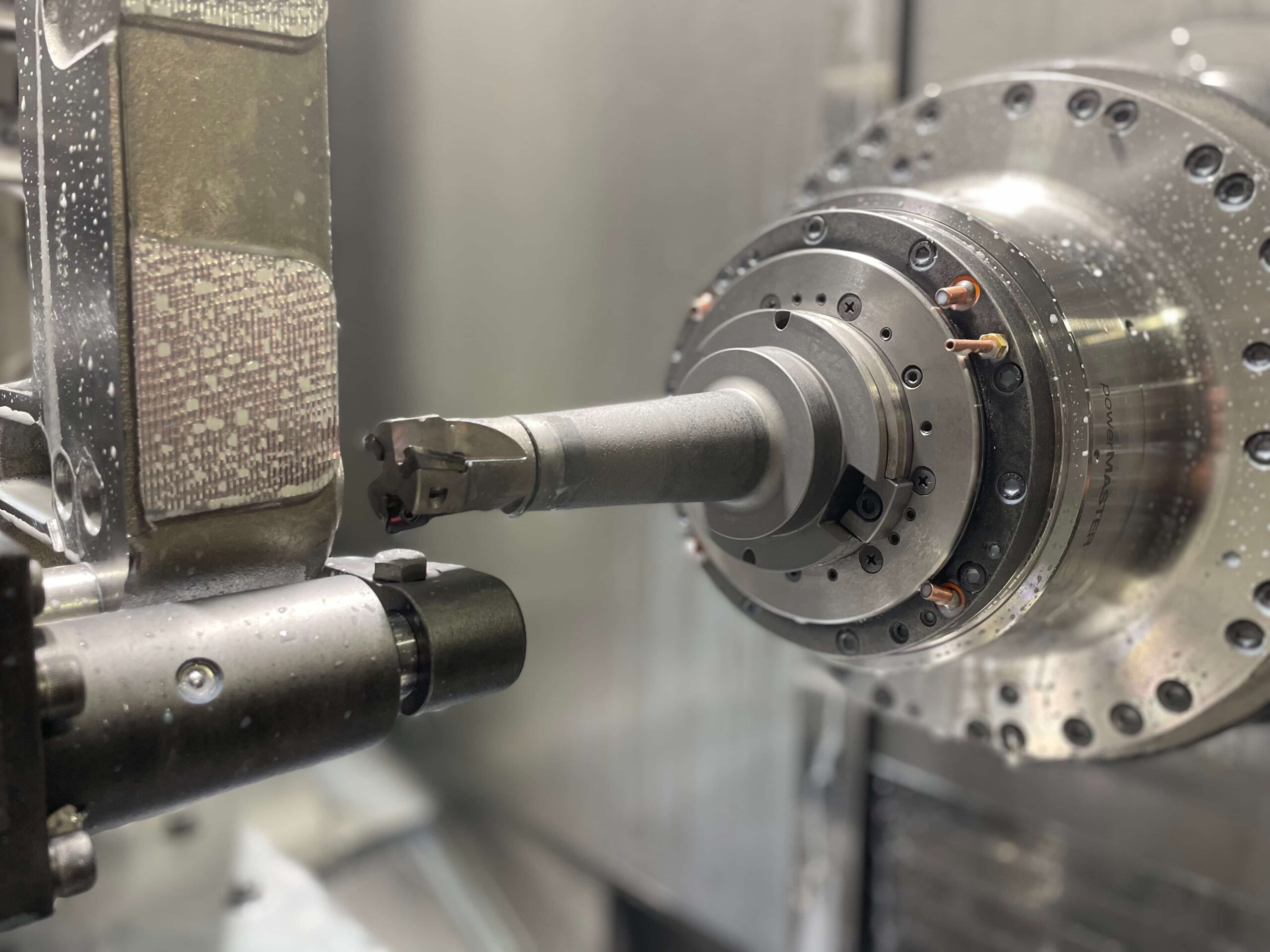

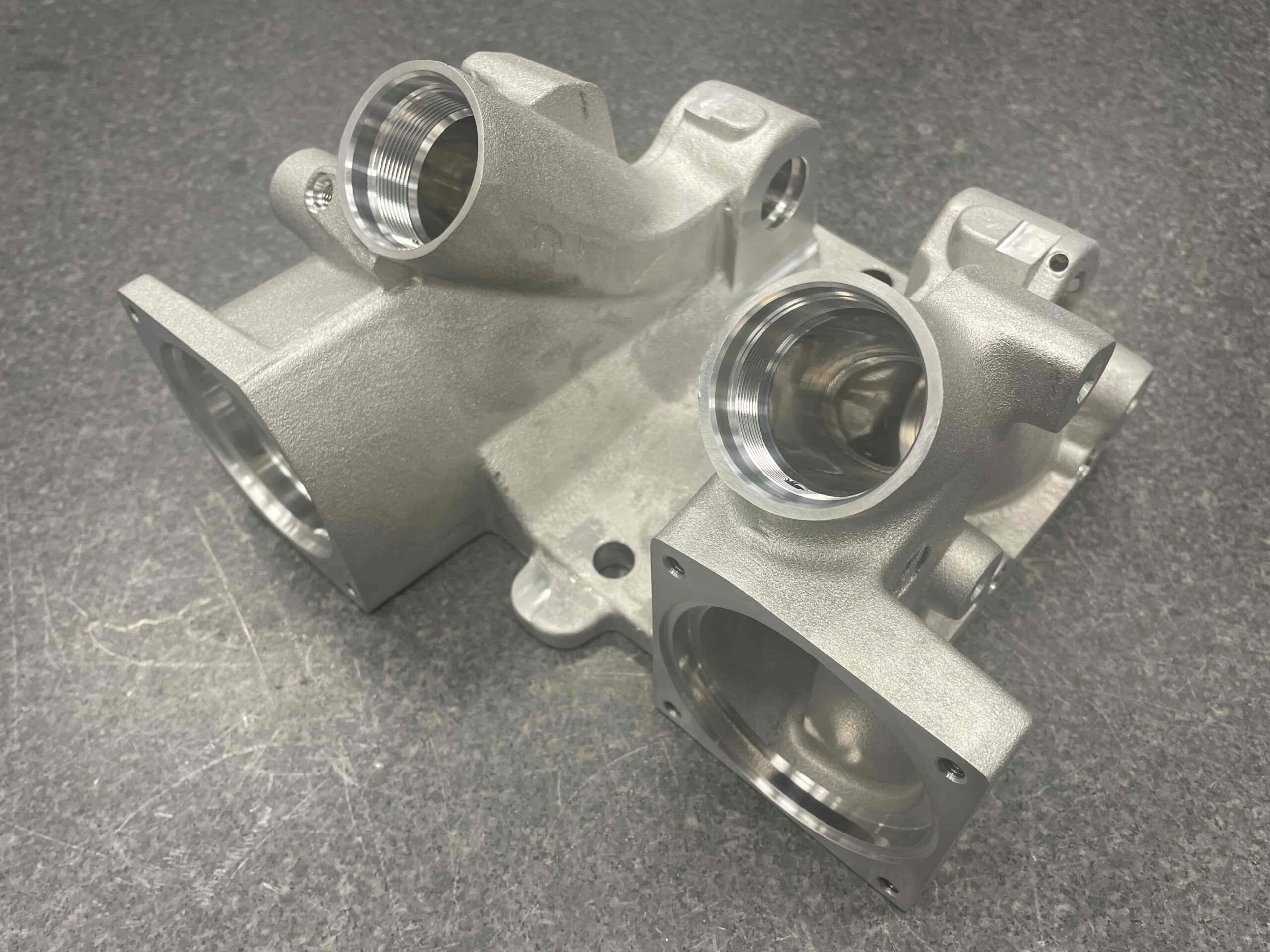

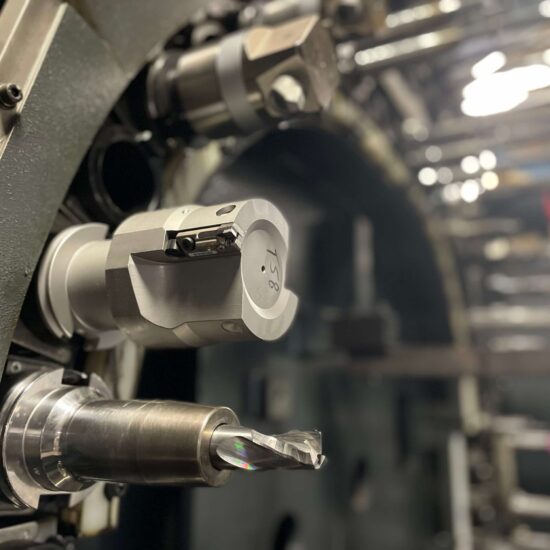

Watry Industries CNC Machining Services

At Watry Industries, we don’t just pour aluminum—we deliver complete, precision-engineered solutions. As one of the most advanced and fully integrated aluminum foundries in North America, Watry Industries offers in-house CNC machining services that deliver exceptional accuracy, efficiency, and consistency for OEMs and manufacturers across industries. With over 65 years of aluminum casting expertise and a facility that spans more than 270,000 square feet, we’ve built a reputation for combining innovation with reliability.