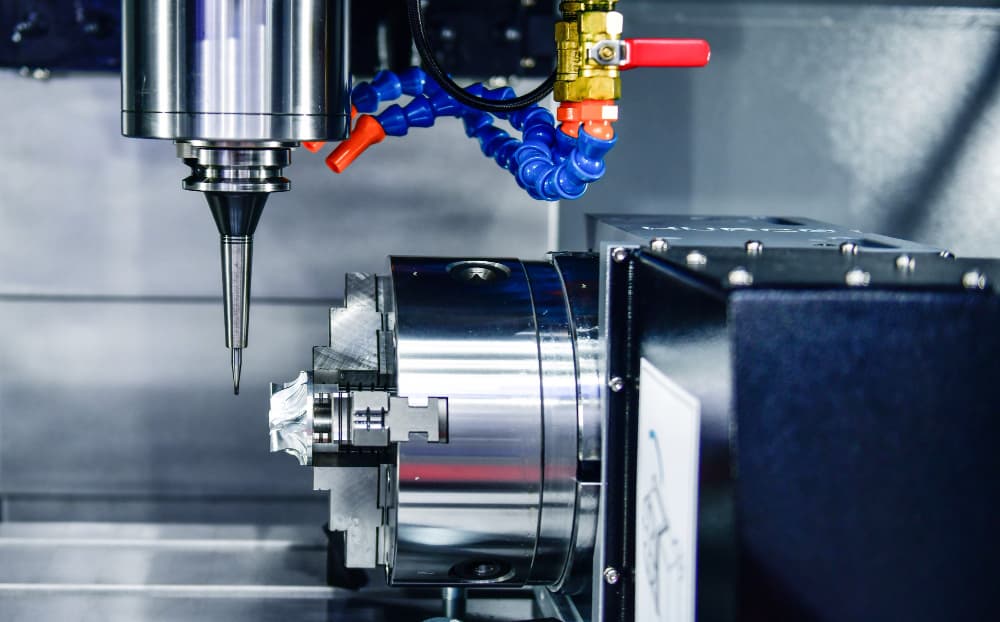

Welcome to our CNC Machining services in Wisconsin, where precision and efficiency converge to transform your manufacturing needs. At Watry, our expert team specializes in CNC Turning and CNC Milling, delivering unparalleled accuracy and reliability in every project. We leverage state-of-the-art technology to craft customized solutions for various industries, ensuring that each component meets the highest standards of quality. Whether you’re in aerospace, automotive, or any other field, our commitment to excellence guarantees superior results, making us a trusted partner in your manufacturing journey. Experience the difference with our tailored CNC Machining services in Wisconsin today.

CNC Machining Wisconsin

CNC Machining Wisconsin: Precision CNC Turning & CNC Milling Machine Services in WI

Comprehensive CNC Machining Services in Wisconsin

At Watry, we offer an extensive range of CNC machining services throughout Wisconsin, focusing on precision and efficiency. Our commitment to excellence ensures that each project is completed to meet the highest standards of quality and accuracy. Within this section, we will delve into the advanced CNC options available through Hastreiter, a leader in the field. We’ll explore how these services enhance manufacturing capabilities, turning innovative designs into tangible products with superior parts and components. Discover how our dedicated team serves the Wisconsin market with tailored solutions that address specific machining needs.

Explore Advanced CNC Options with Hastreiter

When it comes to CNC machining in Wisconsin, Hastreiter’s advanced options present a paradigm of precision and innovation. Our services are tailored to meet the diverse needs of various industries, leveraging cutting-edge machine technology to produce high-quality parts with unmatched accuracy. We focus on delivering customized solutions that enhance efficiency and drive quality, ensuring our clients receive precision-engineered products every time. Whether aiming to create complex components or simple designs, our commitment to quality assurance and precision remains uncompromising. Our manufacturing capabilities extend to CNC turning and CNC milling, harnessing technologically advanced machines that offer exceptional flexibility and reliability. Our CNC solutions streamline production processes, helping businesses improve output and reduce waste. The highly skilled team at Watry collaborates closely with clients in Wisconsin to optimize every project phase, from initial design through final production. By utilizing precision machining techniques, we ensure that each piece is crafted to exact specifications, meeting the strictest tolerances. This dedication to excellence translates into products that not only meet but exceed industry standards, embodying the core values of quality, reliability, and innovation that the Wisconsin machining sector is renowned for. As we serve the diverse manufacturing demands of this region, we take pride in our contribution to the field’s reputation for excellence.

Precision CNC Turning Solutions for Enhanced Bar and Rod Applications

In Wisconsin, precision CNC turning stands out as a crucial service, particularly for bar and rod applications. At Watry, we leverage state-of-the-art technology to maximize machining quality and efficiency, ensuring each component meets strict industry standards. The upcoming sections delve into how CNC turning revolutionizes manufacturing by enhancing product efficiency and quality. We explore the meticulous processes involved in handling various materials like steel to produce high-precision parts. Understanding these techniques provides insights into why CNC turning is integral to modern manufacturing, driving innovative solutions across diverse applications.

How CNC Turning Maximizes Efficiency and Quality

CNC turning technology is a game-changer in the realm of metalworking, especially for creating high-quality bar and rod components. By employing CNC turning machines, we prioritize manufacturing efficiency without sacrificing quality. These advanced machines operate with precision, reducing time spent on manual adjustments and ensuring consistency across all production runs. The end goal is to produce flawless parts that meet specific requirements to a tee. The automation aspect of CNC turning minimizes human errors, enhancing the overall quality of finished products. At Watry, we embrace this technology to handle diverse materials, such as steel, where exactness is paramount. By streamlining machining processes, we significantly cut down lead times, affording clients quicker turnaround for their projects. Moreover, CNC turning’s adaptability is apparent when transitioning between different parts, making it ideal for both small-scale bespoke machining needs and large-scale production lines. This efficiency is crucial in today’s fast-paced industrial landscape, allowing companies to maintain competitive edges. Furthermore, the capability to enhance parts’ integrity by achieving tight tolerances ensures that we meet even the most demanding specifications. Each component produced undergoes stringent testing to verify its integrity and alignment with design plans. Consequently, the integration of CNC turning into our services ensures that our clients in Wisconsin receive only the highest quality, precision-engineered parts, exemplifying our commitment to excellence and performance.

Innovative CNC Milling Techniques for Diverse Industries

In the dynamic sphere of metal machining, CNC milling reigns supreme, offering unmatched precision and flexibility across various sectors. This section will explore how CNC milling plays a pivotal role in modern machine fabrication, detailing its extensive capabilities and unique advantages for industries requiring precise metal component creation. By dissecting how CNC milling integrates with current fabrication trends, we highlight its transformative role in boosting efficiencies and driving innovation. Discover the critical aspects of CNC milling that make it indispensable to today’s robust industrial standards and why it’s a key service offered by Watry.

The Role of CNC Milling in Modern Machine Fabrication

CNC milling is a cornerstone of modern fabrication, heralding a new era of precise component creation across countless industries. This method involves the use of computer-controlled machinery to shape metal and other materials into components with pristine accuracy. In complex manufacturing environments, where precision is non-negotiable, CNC milling stands out by delivering consistently reliable results. For machine fabrication, particularly in the demanding fields of aerospace, automotive, and medical device production, CNC milling proves invaluable. It enables the production of intricate designs that are pivotal in crafting components that meet the highest standards of precision and reliability. Moreover, the capabilities of CNC milling extend to handling diverse materials, such as aluminum, steel, and titanium, accommodating the stringent requirements of high-performance industries. By utilizing CNC milling, manufacturers can produce parts that require complex geometries and tight tolerances, which are often challenging with traditional machining methods. This process not only enhances accuracy but also reduces material waste, optimizing production both environmentally and economically. CNC milling’s integration into modern fabrication underscores its importance in achieving product consistency and quality, a hallmark of the services provided by Watry. Our commitment to employing cutting-edge CNC milling technology ensures we meet even the most demanding fabrication challenges with ease. This dedication translates into superior service for our clients, consistently delivering components that align with sophisticated industrial demands. In an era where efficiency and precision dictate success, CNC milling remains instrumental, fostering innovation and operational excellence across various sectors. Through this dedication, Watry remains a leader in providing comprehensive CNC milling solutions, perfectly tailored to the needs of Wisconsin’s vibrant manufacturing landscape.

Enhancing Machining Capabilities in Wisconsin

Wisconsin is a beacon of machining excellence, renowned for its superior precision and innovation in CNC services. At Watry, we continue enhancing these capabilities, leveraging Wisconsin’s rich industrial heritage. This section delves into why Wisconsin has become a pivotal location for machining, highlighting the state-of-the-art facilities and expertise that foster this development. From stainless steel refinement to rigorous inspections, we’ll explore the foundational elements that support excellence in machining. Join us as we uncover how the supply chain and customer-focused approaches elevate Wisconsin to the forefront of the industry.

Why Wisconsin is a Hub for Machining Excellence

Wisconsin stands out as a powerhouse in machining, not just due to its strategic location but, more importantly, because of its commitment to precision and quality in manufacturing. The state’s long-standing tradition in industrial innovation has paved the way for a thriving machining sector, heavily reliant on cutting-edge technology and skilled labor. Central to Wisconsin’s appeal is its ability to deliver exceptional supply chain solutions, ensuring that materials and components, such as stainless steel, are handled with great care and precision. This efficiency results in faster turnaround times, giving businesses a competitive edge and securing customer satisfaction. Moreover, Wisconsin’s focus on rigorous inspection protocols ensures that every component that goes out the door meets the exacting standards required by industries from aerospace to automotive. The ability to offer detailed quotes customized for each client reflects the deep understanding of diverse customer needs within the state. The consistent demand for such precision services enables local machinists to hone their skills continuously, keeping Wisconsin at the leading edge of technological advancement. Furthermore, the collaboration between suppliers and manufacturers fosters a holistic approach, where customer requirements and industry standards drive innovation. At Watry, we integrate client feedback and industry advancements into our practices, ensuring our processes remain aligned with the highest machining excellence standards. In this way, Wisconsin remains a hub not just of production but of continuous growth and excellence in machining capabilities, making it an ideal locale for these services.

Custom Machine Services at Watry

At Watry, we specialize in offering custom machine services that cater to the unique needs of industries across Wisconsin. Our tailored machining solutions are designed to address specific requirements with precision and efficiency. We’ll explore how our comprehensive services encompass everything from initial contact and consultation to grinding and delivering a precise quote. With a commitment to understanding our clients’ unique needs, Watry ensures each service is adapted to meet tailored solutions. Join us as we delve into the many facets of our custom offerings and how we continue to innovate in the field of machining.

Explore Tailored Machining Solutions for Unique Needs

At Watry, our focus lies in understanding and meeting the diverse requirements of our clients through tailored machining solutions. Our approach begins with an initial contact phase where we actively listen to our clients’ unique needs, ensuring a comprehensive understanding of the project specifications. This personalized approach allows for the development of custom machine services that align precisely with each client’s objectives. By leveraging our extensive experience in the industry, we provide insightful guidance and recommendations, ensuring that every aspect of the machining process is optimized for success. Furthermore, our commitment to quality is reflected in our use of advanced grinding techniques, which enhance the precision of the final components. These techniques are crucial in industries that demand high tolerance and accuracy in their parts. Our team of expert machinists thrives on delivering solutions that not only meet but exceed industry standards, setting a benchmark for excellence. Additionally, we provide detailed quotes, giving our clients clear insights into the scope and cost of their projects. This transparency builds trust and establishes a solid foundation for collaborative partnerships. At Watry, our custom machine services are more than just a service offering; they symbolize our dedication to innovation, reliability, and client satisfaction, ensuring that we meet the unique challenges presented by modern industries.

At Watry, we understand the critical role precision plays in CNC machining, which is why our services in Wisconsin are tailored to meet the highest standards. Whether it’s CNC turning or milling, our skilled team is dedicated to achieving superior craftsmanship. We merge cutting-edge technologies with expert knowledge, ensuring every project is delivered with precision and care. By choosing us, you’re not only investing in top-notch machining services but also in a trusted partner who values quality and reliability. Experience the Watry difference today, and let us enhance your projects with unparalleled precision.

This California government manufacturing page highlights how advanced production sectors including precision machining and related manufacturing technologies support economic growth, offering broader context that complements CNC machining and manufacturing discussions.