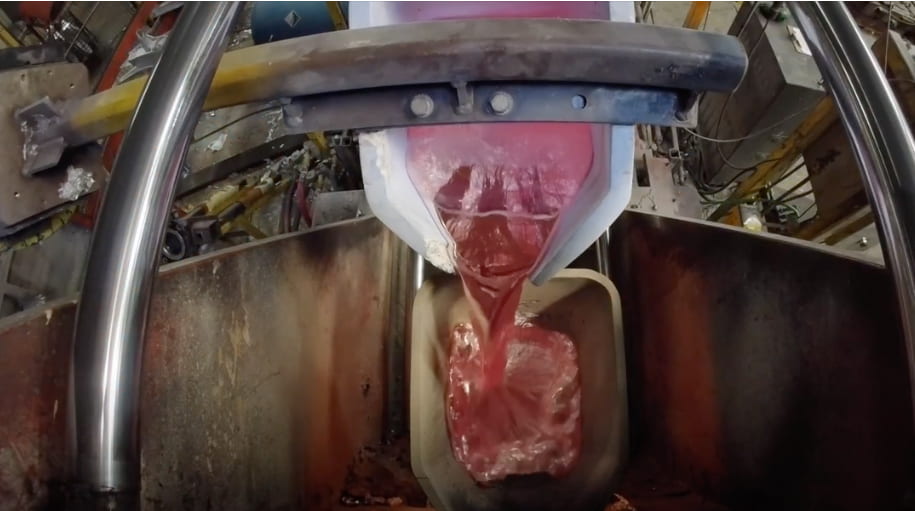

Watry Industries Reverse Tilt Pour Aluminum Castings

Watry Industries is a leading name in the aluminum casting industry—respected for both our long-standing legacy and our commitment to innovation. With over six decades of experience, we’re more than a traditional foundry; we’re a highly automated, technologically advanced manufacturing partner trusted by global OEMs across demanding industries.