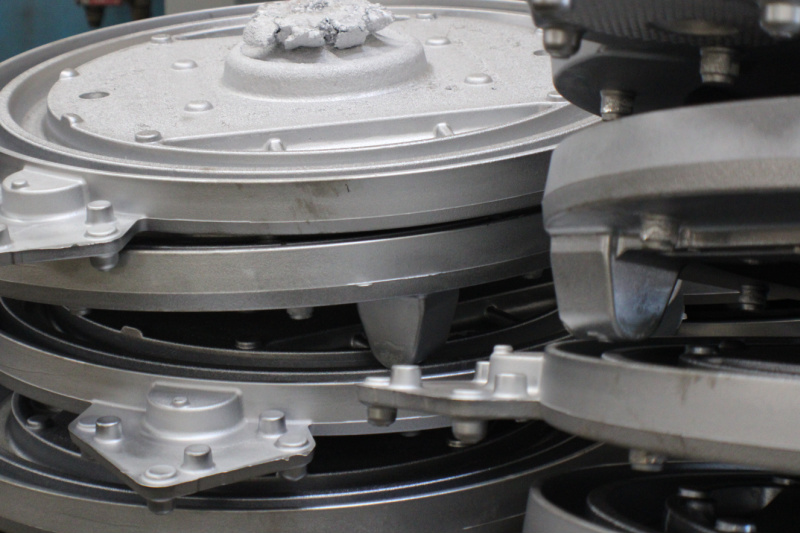

Leveraging decades of experience in permanent mold, semi-permanent mold, traditional tilt pour, and reverse tilt pour aluminum casting, Watry produces components that enhance system efficiency, durability, and motion reliability. Supported by in-house CNC machining, finishing, and testing, Watry ensures complete control from casting to final inspection—streamlining production while maintaining consistent quality.

Advantages of Our Robotics & Automation Aluminum Castings

Watry Industries combines foundry expertise with modern precision manufacturing to meet the demanding requirements of automation system builders and robotic equipment manufacturers.

Key Advantages

- Lightweight Strength

Aluminum castings reduce system weight while maintaining structural integrity—ideal for robotic arms, actuators, and dynamic assemblies.

- Precision & Repeatability

Automated production and machining systems ensure dimensional consistency for seamless robotic alignment and motion control.

- Single-Source Integration

Casting, machining, finishing, and testing are all performed in-house, eliminating delays and ensuring cohesive quality standards.

- High-Performance Alloys

Specialized aluminum alloys deliver exceptional strength-to-weight ratios and resistance to vibration and fatigue.

- Reduced Lead Times & Costs

Integrated processes shorten production cycles and minimize supplier management complexity.

Watry’s expertise allows manufacturers to design lighter, faster, and more efficient systems without compromising reliability—critical advantages in robotics and automation environments.

Typical Applications & Capabilities

Watry Industries supplies Robotics & Automation Aluminum Castings to OEMs building precision equipment for industrial, commercial, and manufacturing automation.

Common Applications Include:

- Robotic arm and joint housings

- Servo motor and actuator enclosures

- End-of-arm tooling brackets

- Vision system housings and mounts

- Gearbox and drive housings

- Control panel and electrical enclosures

- Autonomous vehicle and material-handling system components

Each casting is designed for lightweight durability, with high stiffness-to-weight ratios that enhance motion efficiency and reduce energy consumption. Watry’s design and engineering team works directly with automation manufacturers to optimize each part for manufacturability and long-term reliability.

Integrated Casting, Machining & Finishing

Watry’s integration of casting, machining, and finishing provides robotics and automation manufacturers with a seamless production pipeline. By keeping all processes under one roof, Watry ensures that each aluminum casting meets exact dimensional and cosmetic specifications required for precision systems.

Advanced Machining Capabilities Include:

- (8) DMG Mori NH6300 high-speed horizontal machining centers

- (7) DMG Mori NHX6300 high-speed horizontal machining centers

- (7) OKK 800 high-speed horizontal machining centers

- (5) 400mm–500mm horizontal machining centers

- (1) CNC turning center

- (14) High-speed vertical machining centers

- 6-axis robotic loading of multiple machining centers

These capabilities enable Watry to maintain exceptional precision across large and small components while supporting both low-volume prototypes and high-volume production—ranging from 300 to 600,000 units annually.

Finishing options such as anodizing, powder coating, and pad printing ensure each part not only meets technical performance standards but also aligns with aesthetic and brand requirements common in visible automation equipment.

Testing & Quality Assurance for Robotics & Automation

In automation and robotics, reliability is non-negotiable. Watry ensures every component performs as intended through comprehensive testing and inspection protocols.