Tilt Pour Aluminum Casting – Automated, Efficient, Scalable

Tilt pour aluminum casting is a refined form of permanent mold casting where the mold is slowly tilted during the pour, allowing the molten aluminum to flow more smoothly and reduce turbulence. This method dramatically improves metal flow and reduces gas entrapment and porosity—leading to structurally superior parts.

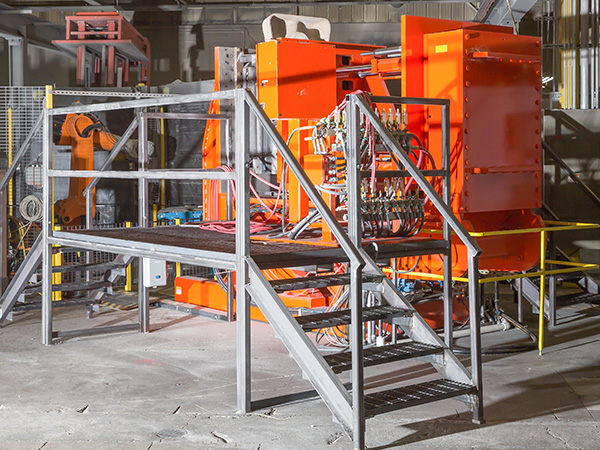

At Watry Industries, we’ve pushed the boundaries of this method by integrating advanced automation, robotics, and engineering systems into every phase of production:

- Robotic Pouring and Extraction: Our automated cells ensure a repeatable and controlled tilt pour process, removing variability and enhancing quality.

- Universal Mold Mounting System: Reduces changeover time and increases tooling versatility across multiple work cells.

- Precision Control Systems: Maintain optimal pour temperatures and tilt rates, resulting in castings with excellent grain structure and dimensional stability.

We produce tilt pour castings ranging from 1 lb. to over 150 lbs., in volumes from 300 units to 600,000+ annually. Our process supports a wide variety of permanent mold aluminum alloys, customized to meet the performance requirements of each customer’s application.