Watry Industries specializes in permanent mold aluminum castings. The permanent mold process employs gravity pouring of metal (which reduces the likelihood of porosity) using steel or cast iron molds. The molds, created economically, are durable enough to produce many castings, which translates into the affordable parts costs you require.

Watry Casting Capabilities

Our Casting Methods

In addition to using permanent mold processes, Watry produces aluminum castings using semi-permanent mold methods as well. This versatility can best serve each application and various casting designs. Want to learn more? Check out our aluminum casting process comparison chart.

Our Equipment

- (15) Reverberatory gas/electric melt furnaces

- 600 – 20,000 lb. holding capacities with 300 – 2,400 lb./hr. melting capacities

- (35) Tilt pour casting machines, 21″ to 40″ stroke, various mold size capabilities

- 6-axis robotic metal pouring, sand core setting, sawing, and extraction

- 360 – 775 lb. load capacities

- 6 station turntable casting cell with robotic pouring and extraction

- **New** CRX-20iA/L Fanuc collaborative robot

- (2) Jet blast units, rotary and continuous feed

- Belt grinding equipment, both manual and 6-axis robotically operated

- Heat treat solution and age equipment

- Air decay and air underwater leak testing

- (8) DMG Mori NH6300 high speed horizontal machining centers

- (7) DMG Mori NHX6300 high speed horizontal machining centers

- (7) OKK 800 high speed horizontal machining centers

- (5) 400mm – 500mm horizontal machining centers

- (1) CNC turning center

- (14) High speed vertical machining centers

- 6-axis robotic loading of multiple horizontal machining centers

- Nordson powder coating line

- 7-stage washer

- Dry off oven

- Full auto powder application booth with manual capabilities

- Online masking

- Continuous belt conveyor

- High-capacity cure oven with **New** Infrared Pre-cure

- Pad printing

- MAGMA casting software

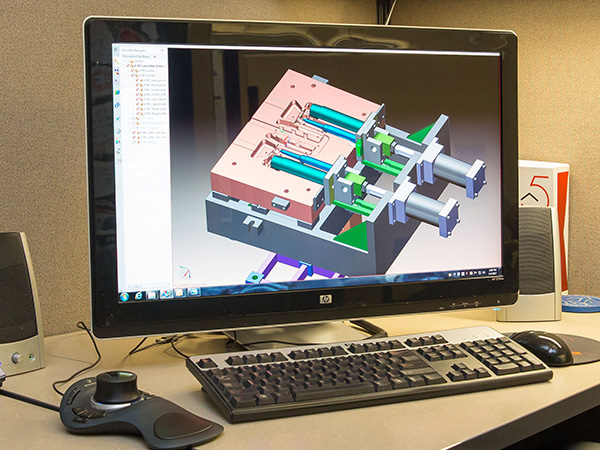

- Solidworks CAD software

- Mastercam CAM software

- In-house Fanuc automation programming

- (3) Hexagon global performance CMM’s

- (1) Romer 7-axis 3D scanning arm

- PC-DMIS programming software

- NSI digital x-ray unit

- Spectrometer

- PLEX ERP management software (quality, production, purchasing, engineering and sales)

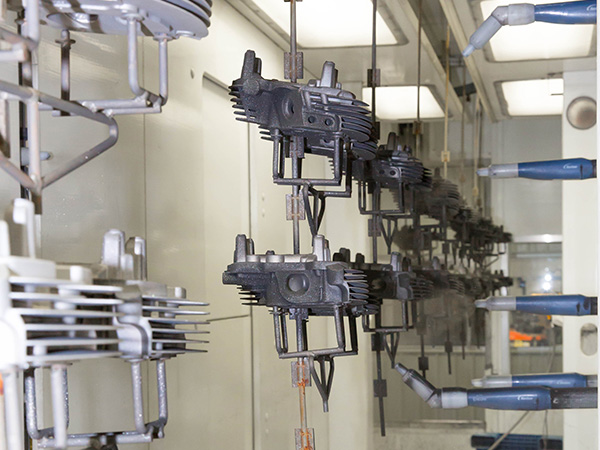

Added Value

Watry’s capabilities extend far beyond a typical permanent mold foundry. As a single source for permanent mold castings, we can reduce your transportation costs and eliminate the headaches that arise in dealing with subcontractors. Learn more about all of our value added services by clicking the links below.

Casting Design Consultation

Watry Industries is truly your single source supplier from casting design consultation through mold design and build, casting, heat treating and precision machining.

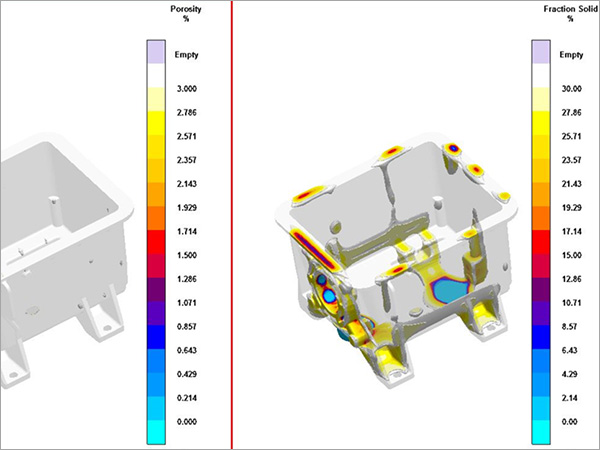

Mold and Fixture Design/Build

Watry utilizes the latest computer software to the design the foundry tooling and simulate the casting process to predict and prevent areas that could be affected by porosity and shrinkage.

Heat Treating

We provide inhouse solution heat treat, artificial age and core sand bakeout to eliminate delays and third party processes. T4, T5, T51, T6, T61, and T7

Precision CNC Machining

Your parts are heat treated, ground, inspected and fully machined to your exact specifications utilizing one of our high speed horizontal or vertical CNC machining centers.

Powder Coating

With our in plant powder coating area, we have a complete 7 stage wash system, and new state of the art powder booth, we can paint the most demanding geometries and meet virtually any paint specification.

Assembly

Watry can assembly your castings to your specifications using standard hardware or specialty purchased components. We verify component installation using a Vision inspection system.

Finishing and Testing

Watry offers a wide varity of secondary finishes and processes to satisfy almost any customer requirement.